To Know Alpha-Pack More

To Know Alpha-Pack More

English

- AP-6BT Automatic 6 Station Rotary & Fill Seal Machine for Pre Made Pouch

- AP-8BT Automatic 8 Station Rotary&Fill Seal Machine for Pre Made Pouch

- AP-8BT-Duplex Automatic Rotary & Fill Seal Machine for Pre Made Pouch

- APHPM-210 Automatic Horizontal Fill Seal Machine for Pre-Made Pouch

- APHPM-210-Duplex Automatic Horizontal Fill Seal Machine for Pre Made Pouch

- APHPM-250G Automatic Horizontal Fill Seal Machine for Pre Made Gusset Pouch

- PM-100 Small Size Sachet Form Fill Seal Packing Machine

- PM-150 Series Medium Size Vertical Form Fill Seal Packing Machine

- PM-190 Series Medium Size Automatic Stick Pillow Pack Packing Machine

- PM-320BE/PM-320B3 Medium Size Vertical Form Fill Seal Packing Machine

- PMW-420E Vertical Form Fill Seal and Multi-head Weigher Combo

- PM-420MN/PM-620MN/PM-720MN Mini Type Pillow Pack VFFS Machine

- PM-430-S2/PM-530-S2 Two Servo Pillow Pack Vertical Form Fill Seal Machine

- PM-520/PM-620 Series Four Corner Seal Box Type Packing Machine

- PM-620J Air Free Liquid VFFS Packing Machine

- MLP-480 Series Multi-Lane Stick VFFS Packing Machine

- MLP-800 Series Multi-Lane Stick Packing Machine

- APSS-5022 High Speed Fully Automatic Side Sealer

- APSS-10022 High Speed Fully Automatic Side Sealer

- APSS-5020BM Fully Automatic Box Motion Side Sealer

- LA-6000 Fully Automatic L-Bar Sealer

- LA-8000 Series Fully Automatic L-Bar Sealer

- LA-460N Fully Automatic L-Bar Sealer

- APW-8040D Automatic Sleeve Type Wrapper Machine

- APT-8040PEII PE Series Shrink Packaging Tunnel

- AHP-390-S3 Economic Top Film Flow Wrapper Machine

- AHP-500-S3 Servo Driven Top Film Horizontal Flow Wrapper Machine

- AHP-600-S3 Servo Driven Top Film Horizontal Flow Wrapper Machine

- AHP-500BB-S4 Bottom Film Flow Wrapper Machine

- AHP-750BB-S4 Bottom Film Flow Wrapper Machine

- AHP-700BBI-S3 Intermittent Bottom Film Flow Wrapper Machine

- AHP-700BM-S4 Box Motion Top Film Flow Wrapper Machine

- AHP-700BBM-S5 Box Motion Bottom Film Flow Wrapper Machine

- SWING-600 Multi-Function Wrapping Packing Machine

- SWING-800 Multi-Function Wrapping Packing Machine

- APTD-150 Automatic Horizontal Bagging Machine

- APTD-200 Automatic Horizontal Bagging Machine

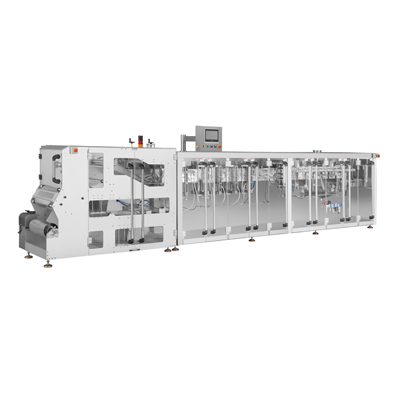

- APHS-140 Horizontal From Fill Seal Packing Machine

- DAPHS-140S HFFS and Doy Pouch with Special Shape

- DAPHS-180Z HFFS and Standup Doy Pouch with Zipper

- AP-12BT-2 Double Heads Rotary Fill + Cap Machine

- AP-12BT-4 4 Heads Rotary Fill + Cap Machine

- 9888L Rotary Type Filling and Capping Machine with Single Lane Design

- 9888L/2 Rotary Type Filling and Capping Machine with Double Lane Design

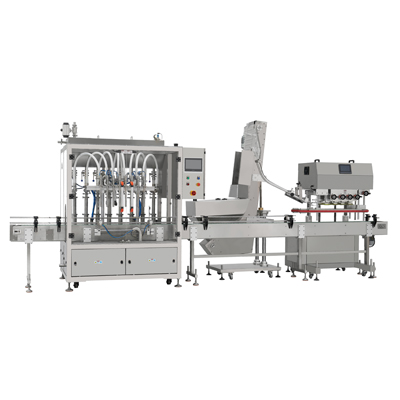

- APFL-840S/860S/880S Fully Automatic Servo Filling Machine

- APFF-2S-1000/APFF-2S-2000 Automatic Following Type Filling Machine

- APCM-1S/APCM-2S Automatic Following Type Capping Machine

- APCM-151A Automatic Intermittent Single Head Capping Machine

- APCM-1208 Automatic Continue 8 Wheels Capping Machine

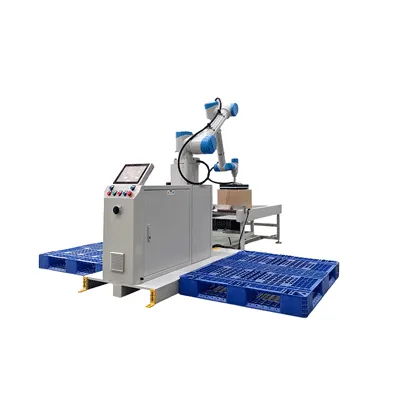

- APR-C20L Collaborate Robot Palletizer

- APR-C20H Collaborate Robot Palletizer

- AP-KB-800 Delta Pick and Place Robot

- AP-KB-1000 Delta Pick and Place Robot

- APXY-8040 Case Packing Machine by XY Axis

- ALB-210 Automatic Top Flat Labeling Machine

- ALB-212 Automatic On Line Top Labeler with Stand

- ALB-213 Side Labeling Machine with Stand

- ALB-220 Automatic Top and Bottom Labeler

- ALB-515 Automatic Positioning Wrap-around Labeler

- ALB-510/ALB-511 Automatic Wrap-around Labeler

- ALB-215 Automatic Horizontal Wrap-Around Labeler for Small Bottle

- APCE-50 Automatic Carton Erector

- APCE-40H18 Automatic Carton Erector

- APCE-40H50 High-Speed Carton Erector

search

WHAT ARE YOU LOOKING FOR?